Polyurethane liquid membrane waterproofing.

For better future living conditions, innovations have been made in the waterproofing industry. Nowadays, high state of the art synthetic polyurethane polymers is used as liquid membranes for the protection of construction work. These are the liquid-applied systems that give long-term flexibility and seal even the most complicated protrusions quickly.

What is polyurethane liquid membrane waterproofing?

Polyurethane is one of the versatile polymers that can be made into fibres, elastomers, flexible and rigid foams, or surface coatings. In the liquid form, this polyurethane protective coating is applied to the surface of the substrate to protect from various types of defects like corrosion, abrasion, weathering, and deteriorating processes.

Polyurethane liquid membrane properties :

- Impermeability - Zero water penetration is necessary.

- Durability - It must be able to retain its integrity when exposed to harsh weather conditions like heat, cold, rain, storm, etc.

- Flexibility - It must withstand the normal movement of building structures that may be due to distortion, earthquake, etc.

- Resistance - The membrane must be resistant to UV, normal wear and tear, and adverse weather.

- Breathability - The membranes must be able to breathe so that the moisture vapours trapped inside the building interiors and the substrate can escape freely.

Advantages of polyurethane waterproofing membrane :

- Seamless finish even in complex structures.

- UV, wear, and weather resistant.

- Easy installation.

- Less thickness ( 2 mm ) in 2-3 layers.

- No significant load increase, even on lightweight decks and roofs.

- It is resistant to alkaline cleaners, battery acid, and fuels.

- Strong adhesion to the substrate.

- Superior performance when applied over the top of the existing waterproofing membrane.

- High tensile strength.

- The hardness and the elasticity give long-term protection against all the natural elements.

Polyurethane liquid membrane waterproofing treatment :

The step-by-step procedure of applying the waterproofing method on the flat roof surface using the polyurethane liquid coating is explained here.

- The first step is to clean the roof surface thoroughly so that it should be free of dust, dirt, grease, and other debris.

- The next step is to fix the cracks on the surface bed by cutting it into the V section, followed by cleaning and filling with polyurethane-based crack filling compound and white cement in the ratio of 1: 2.

- Then, the substrate should be neutralized using the acid application to remove the alkalinity.

- The next step would be to apply a pack of polyurethane primer coats to the surface as an adhesive coat, and it should be allowed to dry completely for at least 8 hours.

- Then, the three successive finishing coats must be applied using a brush with each time coated with two components of polyurethane as per the design ratio.

- Make sure that each coating must be dried for at least 12 hours before applying the subsequent coating.

- This PU coating has to be continued 150 mm up the parapets or walls and at least 100 mm into the rainwater pipes.

- The final polyurethane coating is sprinkled with a layer of 300 microns of sand.

Though the PU coating application is explained in detail, the methods for the surface preparation and its application are mentioned by the product supplier and often supervised by them in the case of large project applications.

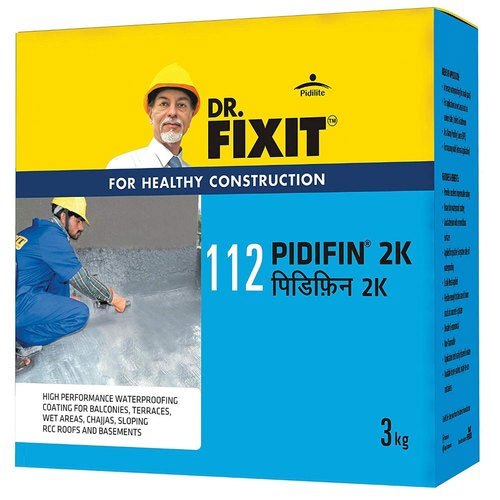

The top 6 Polyurethane waterproofing products available and their rates in the market:

The rate for PU waterproofing services ranges between Rs.75 - Rs.125 / square foot in India. Unlike the other waterproofing systems, this polyurethane coating requires less skillset, supervision, and fast, easy application. So, it is widely used by contractors, consultants, home builders, and homeowners as well.

Though waterproofing is an expensive business, it’s still worth the cost because it prevents cracks and takes all the precautions during the construction stage itself. So, choose the right waterproofing product for the structure durability, less maintenance, energy efficiency, and the well-being of human life.